Contactless Smart Card Bonding Machine Wire Bonding Machinery

Overview Product Description The full auto bonding machine use to weld the antenna and modules of contactless cards. Wit

Overview

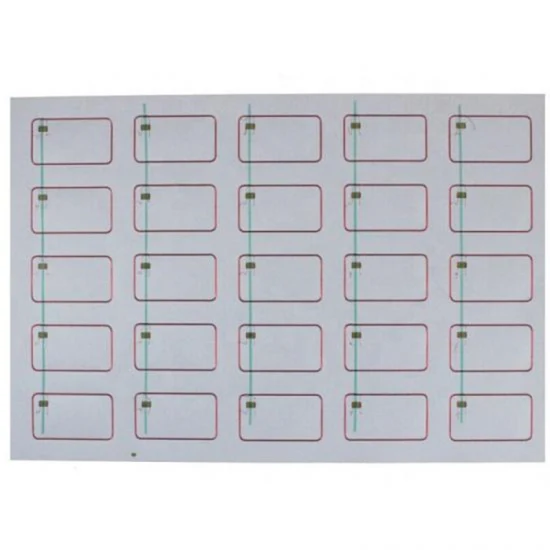

Finished Cards Sample

Basic Info.

| Model NO. | WT-007WBM |

| Controlling Mode | CNC |

| Power Source | Mechanical |

| Condition | NEW |

| Type | Automatic Hole Puncher |

| Hole Number | Customizable |

| Tolerance of Adjustment | 0.01mm |

| Accuracy | Scale of Servo System = 0.01mm |

| Control | Servo Positioning + PLC |

| Applicable Card Materials | PVC, ABS, Pet, PVC/ABS Composite Materials, etc. |

| Transport Package | Vacuum Packing, Standard Shipping Wooden Box |

| Specification | 1400mm(L)*1200mm(W)*1800mm(H) |

| Trademark | WTJX |

| Origin | Shenzhen |

| HS Code | 8462411900 |

| Production Capacity | 100sets/Year |

Product Description

Product DescriptionThe full auto bonding machine use to weld the antenna and modules of contactless cards. With the double pulse current inverter welding, the machine is steady. The machinery automation technologies instead of the traditional manual way to welding the chip, which save the labor and reduce costs, at the same time, ensure the quality of the products.In the machine structure, the machine is easy to operate and maintain, which enhances the service life of machine and the productivity.

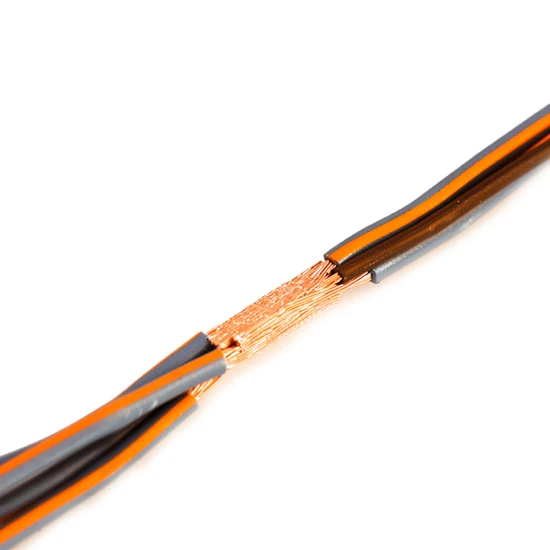

Detailed Photos1. After chip placing and wire embedding, the bonding machine can finish the welding of wire and chip.2. Use the double pulse current inverter welding machine, convenient and directly to monitor the welding, precision and high quality.3. The welding inverter can be adjusted according the production process.4. Servo system controls the position of welding heads, which ensure the welding quality and protect the welding heads.5. It can weld the different layout., each layout setting can be called directly6. The welding heads can be adjusted at X,Y,Z direction.7. No need for air supply.8. Welding with the low noise.9. The machine can be installed 8 heads at most,and1 to 8 welding heads welding at the same time.Product Parameters| Dimension | Approx.1400mm(L)*1200mm(W)*1800mm(H) |

| Weight | Approx. 850kg |

| Power Supply | AC220V 50/60HZ 25A |

| Power | 3KW |

| Air pressure | 6 kg /cm2 |

| Control | Servo positioning + PLC |

| Tolerance of adjustment | 0.01mm |

| Accuracy | Scale of servo system = 0.01mm |

| Applicable materials | The finished module placing and wire embedding |

| Operator | 1 person |

| Output rate | About 1500-4000pcs/hr |

| Product percent of pass | 99% |

Send to us